TECHNOLOGIES

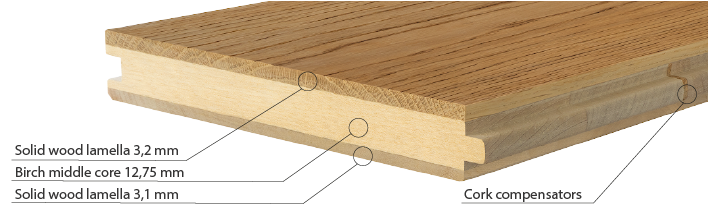

- 3-layer t&g engineered flooring thickness 19.05 mm

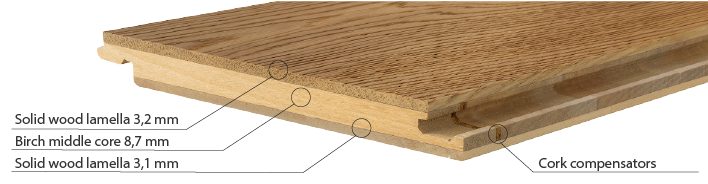

- 3-layer t&g engineered flooring thickness 15 mm

- 3-layer single strip flooring CosLoс thickness 15 mm

- Perfectly balanced symmetrical hardwood construction

- Increased structural stability, fit for all climatic conditions

- Excellent heat and sound insulation

- Environmentally friendly

- Thickness compatible with all types of Coswick mosaic parquet

- Can be installed on underfloor heatingSuitable for high traffic areas

- Lifetime warranty on structural integrity

FEATURES OF CONSTRUCTION

Perfectly balanced symmetrical design with improved stability maintains its dimensions in an extended range of ambience humidity.

Only hardwoods. All three layers are made of hardwood: the top layer is oak, ash or American walnut, the middle layer is birch, and the bottom layer is oak or birch.

Using birch as a middle layer instead of softer softwoods increases the stability of the floorboard, as birch is much more resistant to warping.

Increased thickness of the middle layer. The middle layer is the most important structural element. It takes on the main load, balancing the deforming effect of the thinner upper and lower layers. Accordingly, increasing the thickness of the middle layer improves the stability of the board. This is especially true for wide plank formats – 190 mm or more.

Dimensional symmetry. The upper and lower lamellas have the same thickness of 3.2 mm, so they act symmetrically on the middle layer when environmental conditions change, the loads arising in them balance each other. This increases the balance of the structure and virtually eliminates the possibility of parquet planks warping.

For the top layer, a sawn lamella is used, which eliminates the presence of internal cracks in it. The texture of the sawn lamella does not differ from the texture of the massive floor board.

Cork expansion joints in the middle layer reduce the internal stresses of the wood during humidity fluctuations, providing additional stability to the parquet board.

Super strong connection of lamellas. To connect the lamellas, a special polyurethane hot melt adhesive is used. It is very durable, moisture resistant and elastic. Therefore, the connection retains its properties throughout the entire service life: there is no “aging” effect, the parquet board does not delaminate along the glue line.

Strong and reliable traditional tongue-and-groove connection. Thanks to the ideal geometry and the use of birch wood in the middle layer, the contacting surfaces do not have chips and do not crumple, the appearance of squeaks during operation is excluded.

Environmentally friendly. All auxiliary materials used in the production process are selected taking into account strict requirements for environmental safety. In the finished product, there is no emission of formaldehyde and other substances harmful to human health.

The reliability and durability of the structure is confirmed by a lifetime warranty on the structural integrity of parquet planks.

INSTALLATION

- A three-layer board with tongue and groove connection can be installed in rooms above, at or below ground level.

- It can be installed in rooms with increased loads.

- Installation method – rigid fixation: directly on a concrete base with glue or on a wooden (plywood) base with brackets.

| Dimensions of 3-layer T&G engineered flooring | ||||

|---|---|---|---|---|

| Thickness, mm | 19.05 | 19.05 | 19.05 | 19.05 |

| Top lamella thickness, mm | 3.2 | 3.2 | 3.2 | 3.2 |

| Width, mm | 127 | 190 | 240 | 300 |

| Length, mm | 600…2100 | 600…2100 | 600…2100 | 1450…2950 |

| Microbevel, mm | 0.5 | 0.5 | 0.5 | 1.0 |

| Average length, m | 1.0 | 1.22 | 1.31 | 2.95 |

| Quantity per pack, m2 | 2.0 | 1.86 | 1.88 | 1.77 |

| Dimensions of 3-layer T&G engineered flooring | ||||

|---|---|---|---|---|

| Thickness | ¾” | ¾” | ¾” | ¾” |

| Top lamella thickness | 3.2 mm | 3.2 mm | 3.2 mm | 3.2 mm |

| Width | 5″ | 7 ½” | 9 1/2″ | 11 13/16″ |

| Length | 2’…7′ | 2’…7′ | 2’…7′ | 4 3/4’…9 11/16′ |

| Microbevel | 0.5 mm | 0.5 mm | 0.5 mm | 1 mm |

| Average length, | 3 5⁄16′ | 4′ | 4 5/16′ | 9 11/16′ |

| Quantity per pack | 21.52 sq.ft. | 20.01 sq.ft. | 20.23 sq.ft. | 19.05 sq.ft. |

- Robust, balanced hardwood construction

- High resistance to changes in indoor humidity

- Excellent heat and sound insulation

- Environmentally friendly

- Can be installed on underfloor heating

- Compatible in thickness with other floor coverings

- Optimal solution for living spaces

- Lifetime warranty on structural integrity

FEATURES OF CONSTRUCTION

Robust balanced design with improved stability retains its shape, dimensions and appearance in an extended range of ambience humidity.

Only hardwoods. All three layers are made of hardwood: the top layer is oak, ash or American walnut, the middle layer is birch, and the bottom layer is oak or birch.

Using birch as a middle layer instead of softer softwoods increases the stability of the floorboard, as birch is much more resistant to warping.

Dimensional symmetry. The top and bottom lamellas have the same thickness of 3.2 mm. When environmental conditions change, they act symmetrically on the middle layer, the loads arising in them balance each other out. This increases the balance of the structure and virtually eliminates the possibility of planks warping.

For the top layer, a sawn lamella is used, which eliminates the presence of internal cracks in it. The texture of the sawn lamella does not differ from the texture of the massive floor board.

Cork expansion joints in the middle layer reduce the internal stresses of the wood during humidity fluctuations, providing additional stability to the parquet board.

Super strong connection of lamellas. To connect the lamellas, a special polyurethane hot melt adhesive is used. It is very durable, moisture resistant and elastic. Therefore, the connection retains its properties throughout the entire service life: there is no “aging” effect, the parquet board does not delaminate along the glue line.

Strong and reliable traditional tongue-and-groove connection. Thanks to the ideal geometry and the use of birch wood in the middle layer, the contacting surfaces do not have chips and do not crumple, the appearance of squeaks during operation is excluded.

Environmentally friendly. All auxiliary materials used in the production process are selected taking into account strict requirements for environmental safety. In the finished product, there is no emission of formaldehyde and other substances harmful to human health.

The reliability and durability of the structure is confirmed by a lifetime warranty on the structural integrity of parquet planks.

INSTALLATION

- Three-layer board with tongue-and-groove connection can be installed indoors above, at or below ground level.

- Can be installed on top of floor heating systems.

- Method of installation – rigid fixation: directly on a concrete base with glue or on a wooden (plywood) base with brackets.

| Dimensions of 3-layer T&G engineered flooring | ||

|---|---|---|

| Thickness, mm | 15 | 15 |

| Top lamella thickness, mm | 3.2 | 3.2 |

| Width, mm | 127 | 190 |

| Length, mm | 600…2100 | 600…2100 |

| Microbevel, mm | 0.5 | 0.5 |

| Average length, m | 1.0 | 1.22 |

| Quantity per pack, m2 | 2.0 | 2.0 |

| Dimensions of 3-layer T&G engineered flooring | |||

|---|---|---|---|

| Thickness | ⅝” | ⅝” | |

| Top lamella thickness | 3.2 mm | 3.2 mm | |

| Width | 5″ | 7 ½” | |

| Length | 2’…7′ | 2’…7′ | |

| Microbevel | 0.5 mm | 0.5 mm | |

| Average length, | 3 5⁄16′ | 4′ | |

| Quantity per pack | 21.52 sq.ft. | 21.52 sq.ft. | |

- Improved structural stability

- High resistance to changes in indoor humidity

- Reliable lock connection

- Easy and fast installation

- Excellent heat and sound insulation

- Can be installed on underfloor heating

- Environmentally friendly

- Lifetime warranty on structural integrity

FEATURES OF CONSTRUCTION

Robust balanced design with improved stability retains its shape, dimensions and appearance in an extended range of ambient humidity.

Only hardwoods. All three layers are made of hardwood: the top layer is oak, ash or American walnut, the middle layer is birch, and the bottom layer is oak or birch.

Using birch as a middle layer instead of softer softwoods increases the stability of the floorboard, as birch is much more resistant to warping.

Dimensional symmetry. The upper and lower lamellas have the same thickness of 3.2 mm, so they act symmetrically on the middle layer when environmental conditions change, the loads arising in them balance each other. This increases the balance of the structure and virtually eliminates the possibility of planks warping.

For the top layer, a sawn lamella is used, which eliminates the presence of internal cracks in it. The texture of the sawn lamella does not differ from the texture of the massive floor board.

Cork expansion joints in the middle layer reduce the internal stresses of the wood during humidity fluctuations, providing additional stability to the parquet board.

Lock connection CosLoc of increased strength. Provides easy and fast installation and secure connection of parquet planks without gaps.

Thanks to the ideal geometry and the use of birch wood in the middle layer, the contacting surfaces do not have chips and do not crumple, the appearance of squeaks during operation is excluded.

Super strong connection of lamellas. To connect the lamellas, a special polyurethane hot melt adhesive is used. It is very durable, moisture resistant and elastic. Therefore, the connection retains its properties throughout the entire service life: there is no “aging” effect, the parquet board does not delaminate along the glue line.

Environmental friendliness. All auxiliary materials used in the production process are selected taking into account strict requirements for environmental safety. In the finished product, there is no emission of formaldehyde and other substances harmful to human health.

The reliability and durability of the structure is confirmed by a lifetime warranty on the structural integrity of parquet planks.

INSTALLATION

- Three-layer board with CosLoc can be installed in rooms above, at or below ground level.

- Can be installed on underfloor heating.

- Installation method – floating, on a soft substrate without the use of glue, staples and nails. The planks are joined into a lock on all four sides. If necessary, a board with a lock connection can be reinstalled in another room.

| Dimensions of 3-layer single strip flooring CosLoc 5G | |||

|---|---|---|---|

| Thickness, mm | 15 | ||

| Top lamella thickness, mm | 3.2 | ||

| Width, mm | 127 | ||

| Length, mm | 600…2100 | ||

| Microbevel, mm | 0.5 | ||

| Average length, m | 1.0 | ||

| Quantity per pack, m2 | 2.0 | ||

| Dimensions of 3-layer single strip flooring CosLoc 5G | |||

|---|---|---|---|

| Thickness | ⅝” | ||

| Top lamella thickness | 3.2 mm | ||

| Width | 5″ | ||

| Length | 2’…7′ | ||

| Microbevel | 0.5 mm | ||

| Average length | 3 5⁄16′ | ||

| Quantity per pack | 21.52 sq.ft. | ||